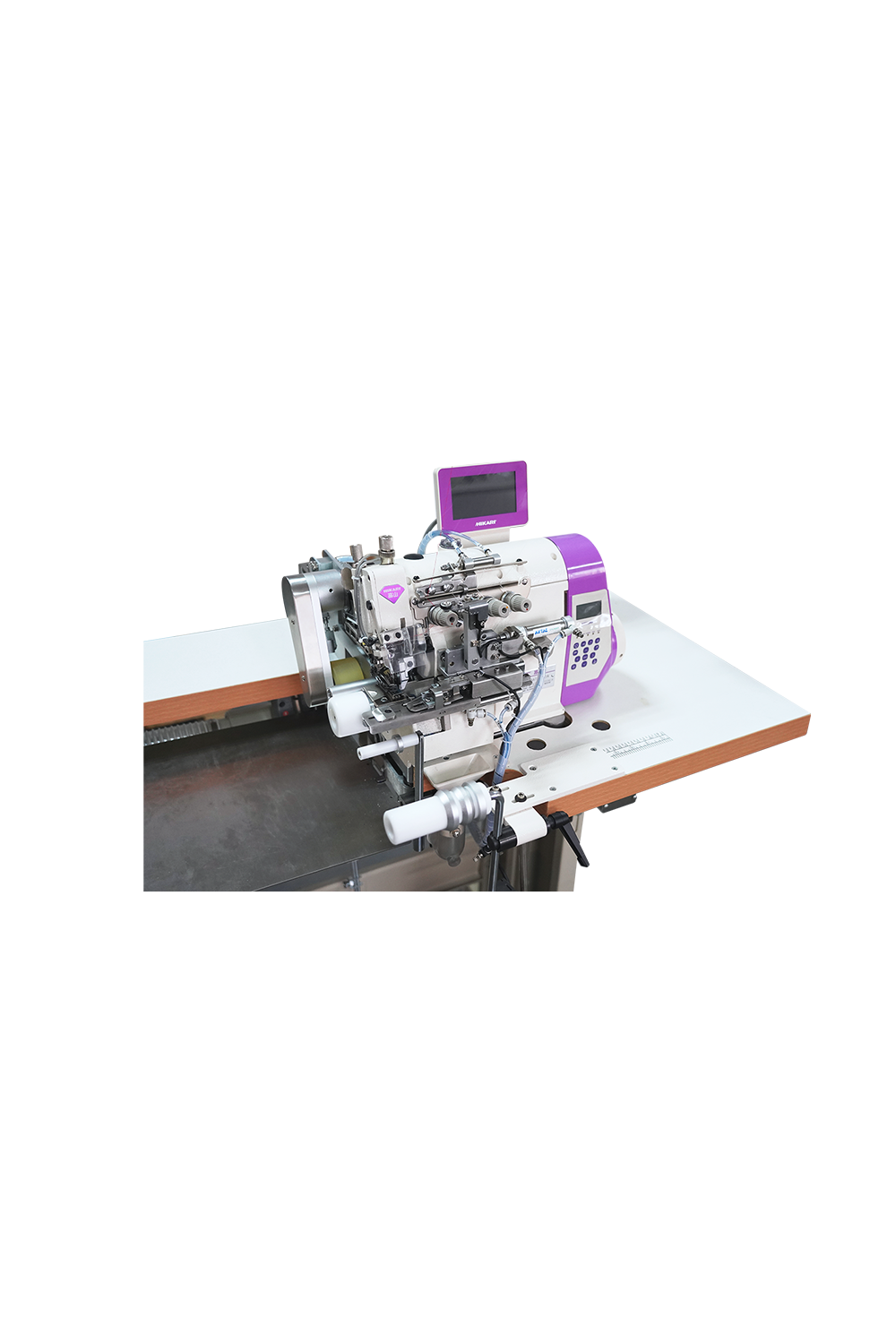

HSAT-K9C | Automatic T-Shirt Neck Joining Machine

Automatic T-Shirt Neck Joining Machine

Description

The HSAT-K9C Automatic T-Shirt Neck Joining Machine is a game-changer in garment manufacturing, specifically engineered for automated round neck binding on underwear T-shirts, casual shirts, and round-neck tops. Featuring our patented three-point positioning system (ZL20192155580.5), this high-tech machine delivers precise, wrinkle-free stitching and uniform collar finishes, boosting production speed and quality like never before.

Ideal for both children’s and adult apparel, the HSAT-K9C ensures a seamless, professional look across a wide stitching range of 28cm to 100cm. Its automatic lift, thread cutting and cleaning, and dual operation modes make it a must-have for high-efficiency garment factories.

Specification

Feature