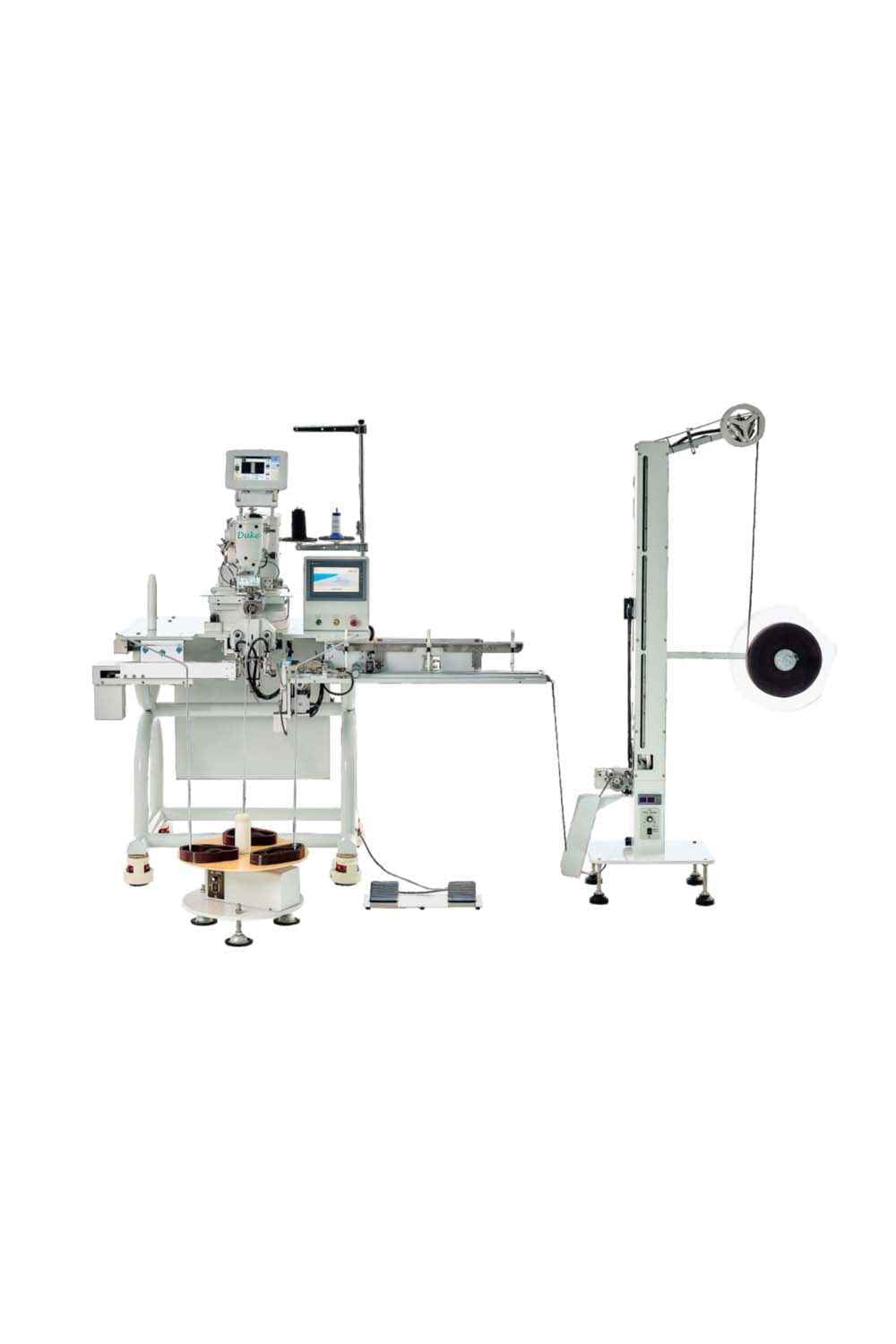

DY B6050-XJ | Elastic Joining Machine

Elastic Joining Machine

Description

The Duke DY B6050-XJ Elastic Joining Machine is engineered to deliver high-precision and high-efficiency elastic band joining for garments, underwear, sportswear, and other stretch-based products. Designed with advanced automation capabilities, the machine ensures consistent quality by preheating the elastic, detecting joints automatically, and preventing production errors.

Its intelligent control system minimizes material waste, eliminates size variation issues, and stops automatically during thread or material shortage—ensuring uninterrupted, stable, and accurate production at every stage.

Key Features

-

Preheats and flattens the elastic band for smooth feeding and stable stitching

-

Automatic stop when material runs out to prevent idle operation

-

Pre-sending system to eliminate size variation caused by elasticity and friction

-

Production-on-demand system to minimize waste

-

Automatic bobbin thread shortage detection

-

Automatic joint detection and cutting

-

Logo recognition and positioning

-

Automatic marker for precise alignment

Technical Specifications

| Specification | Details |

|---|---|

| Working Area | 60 × 50 mm |

| Maximum Sewing Speed | 3000 rpm |

| Stitch Length | 0.05–12 mm |

| Maximum Stitches | 20,000 stitches/pattern |

| Outer Pressure Foot | Electrical |

| Motor | 750W Direct-Drive Servo Motor |

| Needle | DPx5 #12–14 |

| Air Pressure | 0.5 Mpa (1.8 L/min) |

| Stored Programs | 1–999 patterns |

| Power | 2500W |

| Operation Type | Dahao Touch Screen + PLC |

| Supply Voltage | 220V |

| Machine Size | 2100 × 740 × 1600 mm |

| Capacity | 8–13 pcs/min |

| Net Weight | 250 kg |