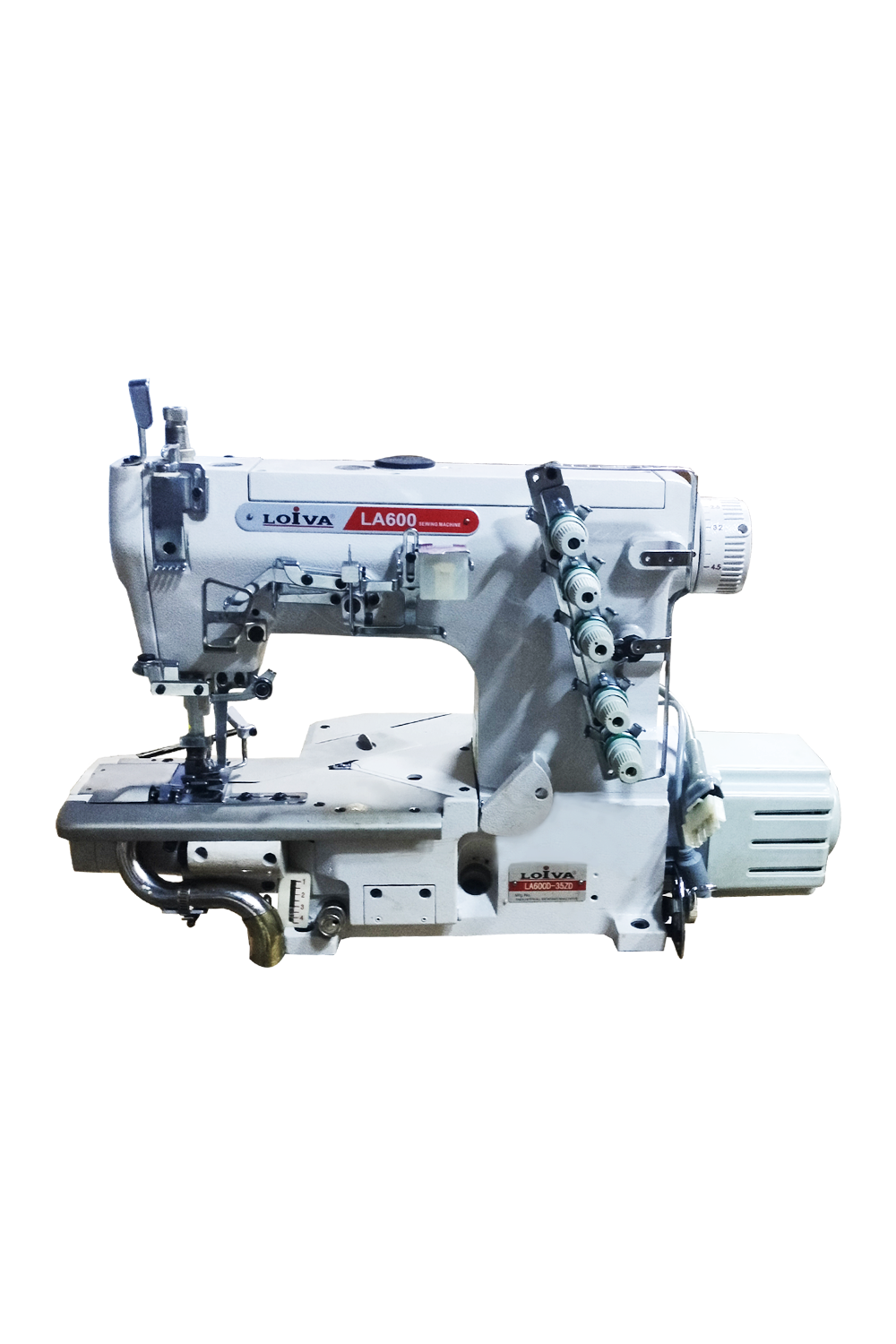

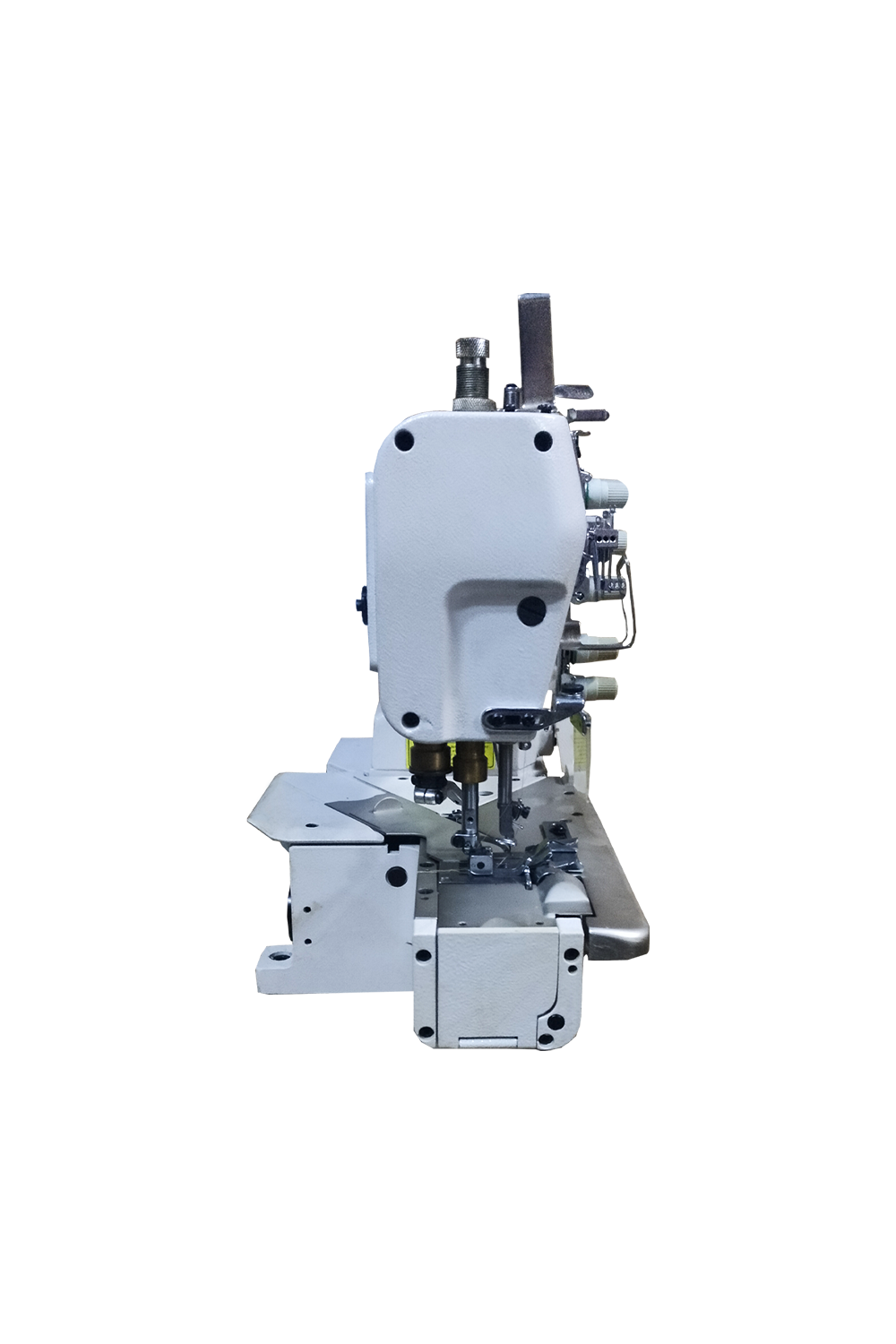

LA-600D-35ZD | Direct Drive Cylinder Bed Interlock with Left Cutter

Direct Drive Cylinder Bed Interlock with Left Cutter

Description

The Loiva LA-600D-35ZD Fully Automatic Hemming Folding Machine is a cutting-edge solution designed to enhance efficiency and precision in fabric processing. Built for industrial applications, this machine automates the hemming and folding process, ensuring consistent quality and reducing the need for manual intervention. It is an ideal choice for the textile, garment, and home furnishing industries, where speed and accuracy are crucial.

Equipped with advanced technology, this machine operates at high speeds while maintaining uniform hemming. Its precision folding mechanism ensures perfectly aligned hems, regardless of the fabric type or thickness. The adjustable settings allow manufacturers to customize the process according to their specific requirements, making it a versatile addition to any production line.

User convenience is a top priority, with an intuitive touchscreen interface that allows for easy operation and quick adjustments. The machine supports a wide range of materials, including cotton, polyester, denim, and blended fabrics, ensuring flexibility across various applications. Additionally, its energy-efficient design minimizes power consumption, reducing operational costs while maximizing output.

Durability and low maintenance further enhance the value of this fully automatic machine. Its robust construction ensures long-term reliability, making it a cost-effective solution for businesses looking to improve productivity and maintain high-quality standards in fabric hemming and folding.

Feature